Labeling Solutions with AI

We have solutions for product identification through vision and artificial intelligence to automatically label products without user intervention.

ADVANTAGES OF VISION COMBINED WITH AI

- Reduction of human errors.

- Increased processing speed.

- Cost reduction by minimizing labor.

- Flexibility in production.

- Waste minimization.

- Improved traceability.

- Regulatory compliance.

- Data collection during the labeling process.

- Better customer experience.

- Integration with other technologies.

VISION AND ARTIFICIAL INTELLIGENCE-BASED LABELING

Our advanced technologies aim to transform the labeling process on production lines by enabling product identification through vision and artificial intelligence, and automatically labeling them with label applicators or using robots.

Who issues the print command?

The system is the one that issues the print command depending on the product needing labeling, which allows us to label highly variable products. Can you imagine an operator not entering the reference they need to label?

What about batches or dates?

Our system is prepared to create automatic batches or to pick up pre-defined dates. We can even print the date, time, minutes, or seconds from the applicator itself, and record all this for traceability.

But what if my product goes inside a box?

Good question! These solutions are really designed to utilize vision, and it might not be effective for all applications, but… what if you have a station where the operator simply shows the product?

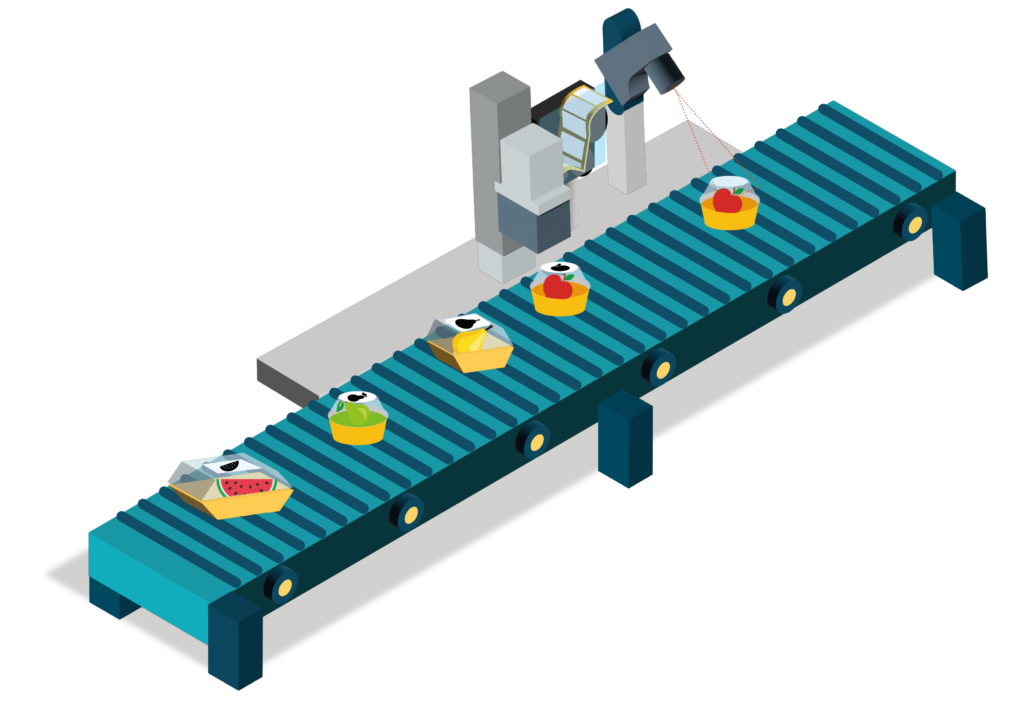

PRODUCT IDENTIFICATION AND LABEL APPLICATION

The artificial vision camera identifies the product and sends a request to the labeling server to apply the label associated with the product.

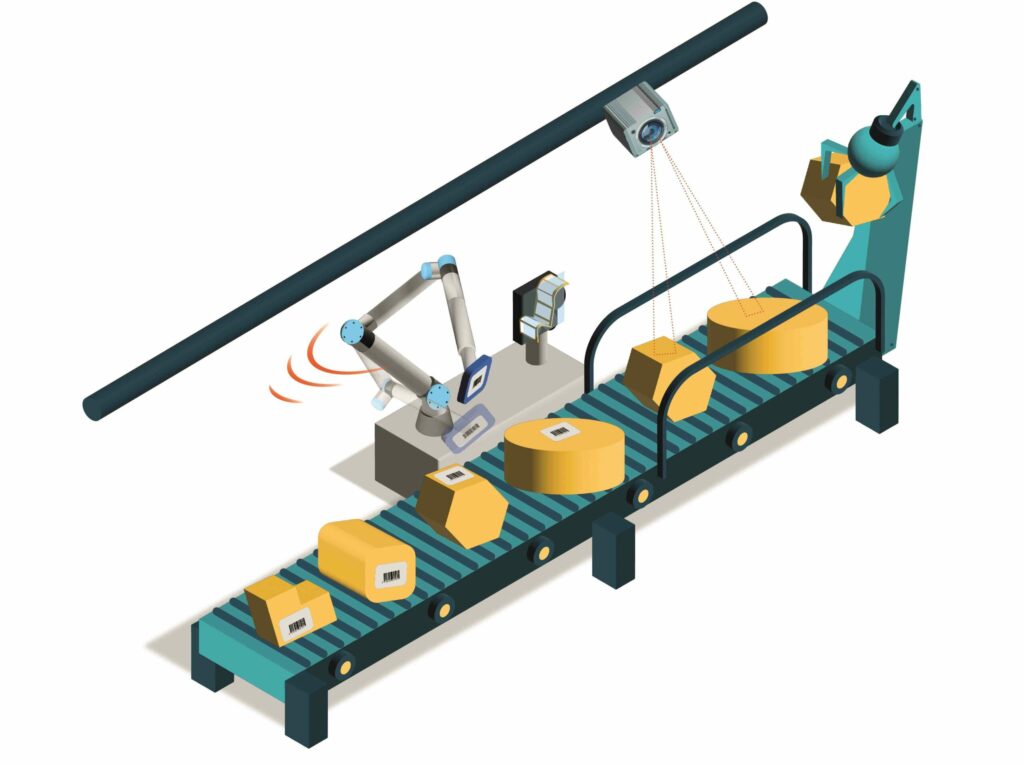

PRODUCT IDENTIFICATION AND LABELING POSITION

The artificial vision camera identifies the product and sends a request to the labeling server to apply the label associated with the product. The position is sent to the robot (label + position).

KEY ADVANTAGES

Increased Efficiency: By eliminating the need for operators to manually input each product reference, we optimize production time and minimize potential human errors.

Versatility: Our solution is adaptable and can label a variety of products on the same production line. This allows companies to switch from one item to another without extended interruptions, thereby increasing operational flexibility.

Assured Quality: Thanks to the incorporation of artificial intelligence, each label is placed with millimeter precision, ensuring that critical information is always legible and correctly positioned.

Lower Costs: Automation not only improves productivity but also reduces operational costs by decreasing reliance on manual labor and minimizing label waste.

Contact us