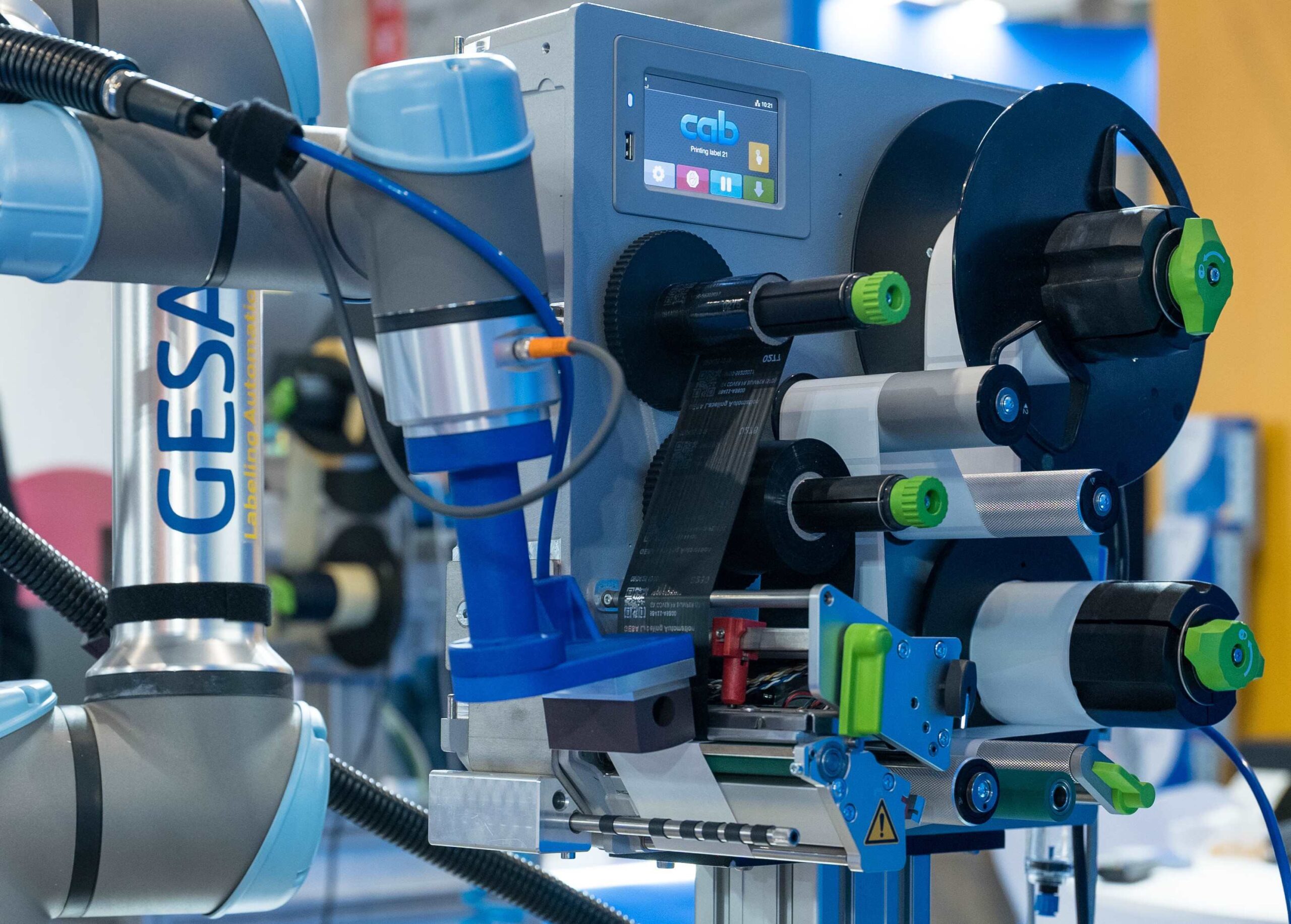

Robotics for Labelling

GESA has made industrial process automation in product labelling accessible to companies of all sizes by using collaborative and industrial robotics.

Advantages of robotics in labelling:

- Cost savings in labelling handling.

- Increased efficiency in labelling processes.

- Flexibility in adapting the labelling application depending on the product..

- Its compact design saves space, and processes can also be easily reprogrammed.

- Frees up your team from the most uncomfortable and repetitive tasks.

- Reduces maintenance cost.

- Applies and reads products for traceability at the same time as the label is applied.

- Reengineering of handling, verification and labeling processes.

GESA & robotics

At GESA, we develop innovative solutions for labelling, verification, and handling of products in collaboration with all types of robots, to perform processes more efficiently, safely, and accurately.

Optimizing operations such as labelling, handling, packaging, or reading requires not only precision, repeatability, and speed, but also a degree of flexibility that allows for the processing of small and varied batches.

CUSTOM-MADE GRIPPERS

We offer grippers specifically designed to adapt to each customer’s needs, enabling effective application on any label size or object type.

Grippers for labelling

We have a range of standard grippers based on common label sizes. These grippers are designed to provide a fast and efficient solution for routine applications, ensuring good performance in label application with both collaborative and industrial robots.

GRIPPER G-102

GRIPPER G-148

· The alliance between robots and our printers transforms labelling into a fast, error-free process, adapting to production needs .

· Our solutions make labelling precise and adaptable to any industrial environment.

special grippers for test tubes

We develop solutions for automatic labelling of test tubes, customizing the type of gripper and fingers based on the product. We control label application, code reading, and labelling traceability.

traditional VS. robotic labelling

In traditional automated labelling, fully automated applicators are often large, expensive, and inflexible. Typically, each applicator is designed for a single task, allowing for very high throughput. As a result, this type of automated labelling is only truly suitable for environments requiring high production rates.

Robotic labelling is a new approach to automation, providing more flexibility to the task and expanding automation to a wider range of cases. We can label based on a series of conditions, offering more options when products are variable.

labelling solutions with robots

GESA develops standardized solutions for product labelling using collaborative and industrial robots, as well as collaborating with engineering firms in the implementation of high-complexity labelling systems with robots.

Contact us