Robot Technology for Labelling

ADVANTAGES OF ROBOTICS IN LABELLING

- Cost-saving in handling of labelling.

- Higher throughput in labelling processes.

- Flexibility in readapting labelling depending on the product.

- It is compact, saves space and processes can be easily reprogrammed.

- Frees your unit from the most uncomfortable and repetitive tasks.

- Reduces maintenance costs.

- Applies and reads products for traceability when the label is applied.

- Process reengineering in handling, verification and labelling of products.

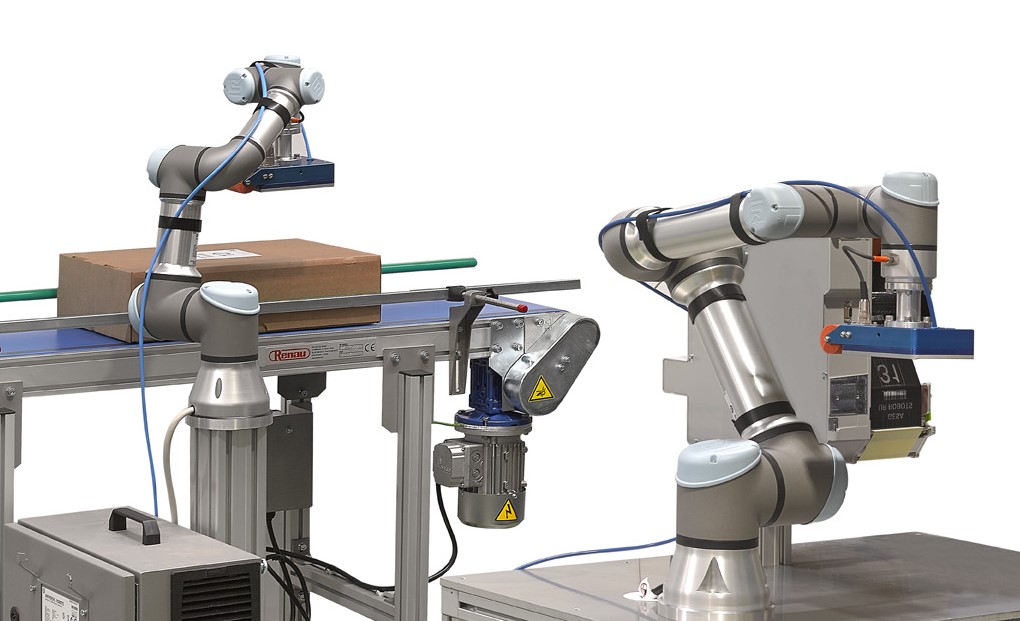

GESA AND COLLABORATIVE ROBOTS

In GESA, we develop new and innovative solutions for labelling, verification and handling of products together with UR robots, in order to perform processes in a more efficient, secure and precise manner.

Optimizing operations such as labelling, handling, packing or readout not only does it require precision, repeatability and speed, but also a degree of flexibility that allows for the outlet of small and varied batches.

GRIPPER G-148

· Robot labelling of fixed or moving products and boxes.

· Robot labelling with strength control and surface adjustment.

· Robot labelling of small labels in multiple surfaces.

· Robot label application and readout for traceability purposes.

SOLUTION TO APPLY SMALL LABELS

TRADITIONAL VS ROBOT LABELLING

In automation of conventional labelling, fully automated applicators are often large, expensive and not particularly flexible. Generally, every applicator is designed for one specific task, which is performed with a high output. As a result, this type of automated labeller is only suited for contexts requiring a very high production.

Robot labelling is a new way to solve automation offering more flexibility regarding tasks and opening automation to a higher number of cases. We can label according to a series of conditions and we will have more options when products are changing.

PARTNER OFICIAL UR

Contact us